Paub meej

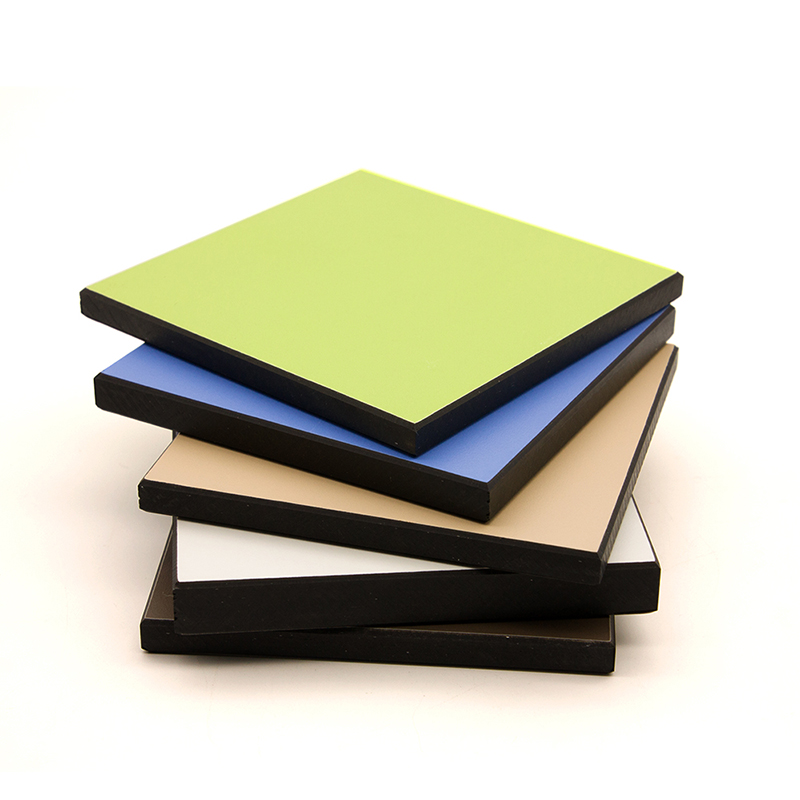

Monco postforming HPL yog tsim los ntawm bendable resin los ntawm kev siv cov txheej txheem thoob ntiaj teb siab heev.Nws yog dav siv hauv cov rooj tog zaum hauv chaw ua haujlwm, txee, rooj, tsev kawm ntawv, kho kom zoo nkauj sab hauv ntawm locomotive thiab tsev neeg kho kom zoo nkauj. npog tsis tau tsuas yog thoob teb chaws tab sis kuj txawv teb chaws.

Cov tsos ntawm Post-forming HPL thiab ib txwm tiaj tus HPL yog tib yam. Txawm li cas los xij, ib txwm HPL tsis tuaj yeem khoov tau thiab tom qab tsim HPL tuaj yeem khoov, zoo li tus thiab ncej tsim rau hauv lub voj voog yog nyob rau hauv cov cua sov tsim nyog.

dabtsi yog khoov los yog post-forming muaj nuj nqi ntawm post-form HPL yog lub sij hawm rhiab heev theoretically, txhais tau tias tus thawj kev ua tau zoo thiab yooj yuav txawv tom qab cia ib lub sij hawm. Thaum, nws tsis yog qhov tseeb thiab qhov tseem ceeb tshaj plaws yog qhov chaw cia khoom. Piv txwv li, qhov yooj yim los yog dabtsi yog khoov yuav qis dua, yog tias cov khoom muab tso rau hauv qhov kub thiab txias heev. Kev Taw Qhia Kev Ua Haujlwm thaum siv daim ntawv HPL tom qab Nws yog qhov theoretical tias kev tshaj tawm cov nplooj ntawv HPL yog qhov zoo nrog phau ntawv yog tias nyob rau hauv txaus siab thiab kub. Thaum, nws raug nug txog qib zoo ntawm cov khoom tiav los ntawm kev ua haujlwm ntawm phau ntawv. Yog li ntawd, txawm tias qhov zoo ntawm cov ntawv xovxwm tshuab, zoo npaum li cas, qhov kub thiab txias yog ob qho kev tsim nyog tshaj plaws.

Taw qhia ntawm MONCO POSTFORMING HPL

Postforming HPL muaj ntau yam zoo heev. Nws qhov tseem ceeb tshaj plaws yog qhov muaj peev xwm khoov rau hauv qhov sib txawv arcs rau rooj tog. Nws tuaj yeem tswj tau qhov kev ruaj ntseg hauv qhov kub thiab txias, thiab tib lub sijhawm, qhov postforming HPL kuj muaj lub zog siab thiab tuaj yeem tiv taus cov khoom loj.

Postforming HPL muaj ntau yam qauv tsim thiab nto tiav. Lub rooj tsavxwm tuaj yeem txiav thiab kho rau txhua qhov chaw raws li cov neeg siv khoom xav tau, haum rau ntau qhov chaw tsim vaj tsev tsim thiab kho kom zoo nkauj.

Cov yam ntxwv tseem ceeb ntawm Postforming HPL yog lawv qhov yooj yim, uas tso cai rau kev khoov yooj yim, txiav, splicing thiab lwm yam kev ua haujlwm. Ntau cov duab ntawm refractory Board tuaj yeem ua raws li cov neeg siv khoom xav tau, txhim kho qhov yooj thiab plasticity ntawm cov txheej txheem ntau lawm.

Khoom nta

1. Kev kub siab ua haujlwm zoo: Lub Postforming HPL muaj qhov ua tau zoo ntawm qhov kub thiab txias, ua haujlwm zoo nyob rau hauv qhov chaw kub kub, tuaj yeem siv tau ntev, thiab tuaj yeem tiv taus qhov kub thiab txias txog 2000 ℃.

2. Kev ua haujlwm zoo rwb thaiv tsev: Lub rooj tsav xwm nkhaus refractory muaj kev ua haujlwm zoo rwb thaiv tsev, uas tuaj yeem tiv thaiv cov neeg ua haujlwm thiab cov khoom siv hauv qhov chaw kub kub.

3. Lub teeb yuag thiab yoog raws:Postforming HPL yog lub teeb yuag thiab hloov tau yooj yim, ua rau lawv yooj yim rau txheej txheem thiab nruab. Lawv tuaj yeem ua rau cov khoom siv rooj tog nrog cov nkhaus sib txawv raws li qhov xav tau, xws li cov rooj zaum khoov, txee nkhaus countertop, thiab lwm yam.

4. Postforming HPL yog cov khoom siv refractory zoo heev nrog cov khoom zoo heev thiab cov yam ntxwv, siv dav hauv ntau qhov chaw, thiab tau ua haujlwm zoo rau kev txhim kho thiab kev lag luam.